What GOST and SanPiN say

Technologies for raising poultry have come so far that the state is no longer able to regulate the shelf life of what the producer has grown. However, GOST recommends adhering to certain time limits, which the manufacturer cannot increase.

When leaving the enterprise, chicken carcasses are usually divided into:

- cooled down (temperature no higher than 25 °C);

- chilled (from -2 to 4 °C inclusive);

- frozen (not higher than -12 °C);

- deep frozen (not higher than -18 °C).

The shelf life is as follows:

1. At temperatures from -2 to 2 °C inclusive:

- whole chilled carcasses – no more than 5 days;

- parts of carcasses - no more than 2 days from the date of slaughter.

2. Frozen carcasses stored at -12 °C:

- entirely – no more than 8 months;

- cut into parts – 1 month.

3. Frozen carcasses stored at a temperature not exceeding -18 °C:

- entirely – no more than 12 months;

- divided into parts – 3 months.

4. If freezing and storage is carried out at a temperature not exceeding -25 °C:

- whole carcasses are stored for no more than 14 months.

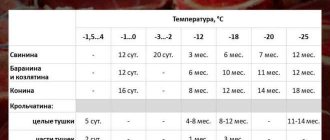

SanPiN regulates the storage of poultry and prepared meals in public catering establishments and puts forward the following requirements (see table):

Shelf life of chicken meat products according to SanPiN

Poultry storage

Cooling and freezing of poultry • Air-droplet cooling of poultry (hydroaerosol-evaporative); • shock freezing in tunnels and chambers • installations with film evaporators to produce ice water 0.5...1.5 °C (screw cooling of carcasses in baths); • ventilation and air conditioning systems for technological and production workshops, expeditions, and transport corridors. Obtaining a wide range of high-quality products using poultry meat predetermines the need to use high-quality natural raw materials. Poultry meat, as a perishable product, is subject to immediate refrigeration immediately after production. In solving problems of preserving the natural properties of poultry meat, as well as other food products, cold undoubtedly plays a leading role. Poultry meat, depending on the temperature in the thickness of the muscle (for poultry products - in the thickness of the product) is divided into: 1. fresh - meat immediately after slaughter and processing, having a temperature of not lower than 25 ° C; 2. cooled - meat kept in natural conditions or in ventilated chambers, having a temperature close to the ambient temperature, but not higher than 25°C; 3. chilled – meat after cooling, having a temperature not lower than 0°C and not higher than 4°C; 4. frozen (deeply chilled, supercooled) - meat after freezing, having a storage temperature not higher than -2°C and not lower than -3°C (for poultry carcasses); 5. ice cream - meat after freezing, having a temperature not lower than -8°C; 6. defrosted – meat after defrosting, having a temperature of at least 1°C. Cooling of poultry carcasses. Gutted poultry carcasses that have been washed are cooled by immersion or hydroaerosol-evaporation methods in one or two stages. For single-stage immersion cooling with free movement of birds, submersible auger units are used. Carcasses after washing are automatically dumped into evisceration containers directly into a pre-cooling bath with running tap water and cooled for 10 minutes. Then the carcasses are placed in a final cooling bath with ice water at a temperature of 0°C to 2°C and cooled for 25 minutes. The minimum supply of fresh water to immersion baths during the cooling process is recommended in the amount of 2.5 liters per carcass weighing 2.5 kg or less. After immersion cooling in water, the carcasses are kept to allow free moisture to drain for 15 minutes. After slaughter of animals, incl. poultry, due to the action of tissue enzymes, autolytic changes in muscle tissue occur, accompanied by post-mortem termination and subsequent muscle relaxation, characterized as the process of meat ripening. The currently practiced intensive cooling in ice water causes, along with the natural finish, an additional increase in the hardness of the meat due to cold muscle contraction. Subsequent freezing of carcasses does not have the best effect on the quality indicators of the finished product, since by this time the muscle fibers are in the most reduced state, forming a strong structure. As a result, the availability of enzymes, the solubility of proteins, and the moisture-holding capacity of the tissue are minimal, and during defrosting and heat treatment, the loss of juice is greatest. As a result, the product becomes less juicy and less digestible. An acceptable minimum period for ripening broiler carcasses is considered to be keeping them after cooling for at least 4 hours in a refrigerator at a temperature of 0...2°C. A guarantee of good quality of the final product is considered to be keeping the carcasses after cooling for at least 6…8 hours. For poultry meat sold chilled, the quality problem caused by the release of muscle tissue from the state of rigor mortis can be quite successfully solved during the subsequent refrigerated storage of carcasses in refrigerator chambers after cooling. The solution to the problem of meat ripening can be facilitated by the technology of two-stage cooling of poultry carcasses, based on the results of an analysis of the processes of heat removal and post-mortem rigor of carcasses during cooling. The temperature achieved at the first stage ensures the sanitary well-being of the product, and subsequent further cooling in the storage chamber creates favorable conditions for maximum resolution of the rigor state. Hydroaerosol - evaporative cooling of poultry carcasses is carried out in specially equipped installations or chambers by sequentially moving carcasses fixed on suspensions through a zone with a hydroaerosol medium and a cold air circulation zone. The hydroaerosol environment is created using nozzles that spray water from the water supply network. When entering the hydroaerosol zone, the surface of the carcasses is moistened by circulating cold air with a temperature from -1°C to 0°C and a movement speed of up to 3m/s. The duration of one-stage hydroaerosol-evaporative cooling of poultry carcasses weighing up to 1.2 kg is 1-1.2 hours. Freezing poultry carcasses. Chilled poultry carcasses are sent for freezing. Poultry is frozen in air or by immersion in a coolant. The faster the process of freezing poultry proceeds, the higher the quality of the product, shelf life and less shrinkage. Air freezing of poultry carcasses packed in standard transport containers (cardboard boxes) in a group manner is carried out in freezers at an air temperature not higher than -23°C, a relative humidity of at least 90% and a circulation speed of up to 4 m/s. It is recommended to maintain the temperature and air circulation speed uniform throughout the working volume of the freezing device. The freezing process is considered complete when the temperature in the thickness of the pectoral muscle reaches -8°C. The duration of the freezing process, depending on the type and fatness of the bird, its packaging and the type of freezing devices used, ranges from 2.5 to 40 hours. From the standpoint of consumer quality and technological properties, the widely accepted technology of freezing carcasses immediately after cooling, which aggravates all the undesirable consequences of rigor mortis, is not entirely successful, which, however, has to be put up with due to the reality of long-term transportation of perishable raw materials and, most importantly, the need to create food tanks. The following classification of the intensity of the freezing process has been adopted depending on the speed of movement of the interface: 1. slow - about 0.5 cm/h; 2. fast – from 0.5 to 5 cm/h; 3. ultra-fast - from 5 to 10 cm/h; 4. ultra-fast – more than 10 cm/h; In relation to poultry carcasses, slow freezing is typical for air group freezing of carcasses placed in transport containers (wooden boxes, corrugated cardboard, etc.); fast - for air piece freezing of carcasses without placing them in transport containers at low temperatures and intensive circulation of cooling air, for submersible (immersion) freezing in non-boiling liquids with mandatory packaging of carcasses in consumer containers - individual bags made of polymer films, in plate-based devices. Ultra-fast freezing is achieved when using cryogenic media, ultra-fast - when cryogenic freezing of objects of small thickness. When meat is quickly frozen, numerous small ice crystals form simultaneously both inside the muscle fibers and outside them - in the interfiber spaces and are distributed fairly evenly throughout the entire volume of the tissue. The ice formation caused by this form is very insignificant, which has a positive effect on the reversibility of recovery processes after defrosting. With slow freezing, the formation of a relatively small amount of ice crystals begins between the fiber bundles, where the concentration of tissue juice is small. The crystals gradually increase in size due to moisture migrating from the cells and fibers. Large crystals have a noticeable mechanical effect on the tissue, damaging and disrupting its natural structure, which is not completely restored when defrosted. Nowadays, it is almost universally pleasant to freeze poultry carcasses after they have been cooled to a temperature regulated in the thickness of the pectoral muscles of no higher than 4°C. The surface temperature of the carcass after cooling can range from -1 to 2°C. Subsequent operations in the technological process: sorting, packaging, weighing, carried out according to regulations in rooms with an air temperature not higher than 12°C. The final freezing temperature of poultry carcasses is determined by the current Technological Instructions for the production of poultry meat, which agrees that the freezing process is considered completed when the temperature in the thickness of the pectoral muscle reaches -8°C. As the temperature of the cooling medium decreases, the duration of freezing decreases almost proportionally. When the air temperature decreases by every degree in the temperature range from -18 to -25°C, the freezing time is reduced by 4.5%. It has been established that the most effective way to increase the heat transfer coefficient in the air is to increase the air circulation speed to 5...6 m/ c. Storing chilled poultry carcasses. Chilled poultry carcasses are stored in refrigerators at temperatures from 0°C to 2°C and a relative humidity of at least 85%. The shelf life when storing chilled carcasses is no more than 4 days from the date of production. Storage of frozen poultry carcasses. Frozen poultry carcasses are stored in refrigerators at an air temperature no higher than -18°C and a relative humidity of at least 90%. An increase in air temperature in storage chambers during loading and unloading of poultry is allowed by no more than 3-4°C. Cooling of semi-finished products. Cooling of semi-finished products made from fresh poultry meat is carried out in an air environment individually or after group packaging in one row in height in a standard transport container. Semi-finished products are cooled at air temperature from -1°C to 0°C, relative humidity of at least 85% and air circulation speed up to 3m/s. The cooling process is considered complete when the temperature within the product reaches no higher than 4°C. The duration of cooling of semi-finished products, depending on the initial temperature, type, packaging, and cooling devices used, ranges from 0.5 to 4 hours. Freezing semi-finished products. Semi-finished products are frozen at an air temperature no higher than -18°C, a relative humidity of at least 85% and a circulation speed of up to 4 m/s. The freezing process is considered complete when the temperature within the product reaches no higher than -8°C. The duration of freezing semi-finished products, depending on the initial temperature, type, packaging, and freezing devices used, ranges from 1 to 8 hours. Storage of semi-finished products. Chilled semi-finished products are stored in refrigeration chambers at a temperature from 0°C to 2°C and a relative humidity of at least 85%, natural - no more than 72 hours, chopped - no more than 24 hours from the end of the technological process, including at the manufacturer, respectively not more than 12 hours and 6 hours. Ice cream semi-finished products are stored in refrigerators at a temperature not higher than -12°C and a relative humidity of at least 90%, natural - no more than 3 months, chopped - no more than 1 month from the date of production; at a temperature not higher than -18°C and a relative humidity of at least 90%, natural - no more than 4 months and chopped - no more than 2 months from the date of production.

How to choose fresh

The quality of the prepared dishes and your health will depend on how fresh the chicken you bring home is.

If the chicken is packaged, you need to look for the production date on the label. If there is none, feel free to rip the packaging. The buyer has the right to be informed about the quality of the goods.

They say about the freshness of a chicken carcass:

- Smell. Even without experience, a person can determine whether chicken is “smelly.” Feel free to bring the carcass to your nose. You need to smell the incision site on your stomach. Fresh meat has almost no smell. Any smell should stop you, it’s better not to buy such chicken.

- Mucusiness. The skin of fresh chicken without packaging may be a little dry, this is normal.

Do you know that…

Before slaughter, birds are prohibited from being given a whole list of feeds that impair the taste and affect the smell. However, manufacturers neglect this in order to reduce the cost of products.

Broiler chickens sold in stores are often wet. There are several reasons for this:

- To increase weight, they increase the moisture content of chicken meat (this is beneficial to producers).

- Before shipping, chicken is washed with special disinfectants (this extends shelf life).

However, moisture and mucus are different things. Mucused meat may not have an unpleasant odor if it is washed with special solutions. But identifying the presence of mucus is not difficult; the main thing is to look closely and touch the carcass with your hand.

But you don’t need to pay attention to color. A pale chicken is no worse than a yellow one. In order for the chicken to have a marketable appearance, it is fed corn before slaughter.

The color of the bird does not affect the quality and freshness of the meat; the broth from yellow chicken will simply be yellower

Storage conditions

The shelf life of poultry meat depends on the temperature and air humidity in which the product will be located.

- The plucked and gutted carcass can remain on the refrigerator shelf for up to 5 days. And if the meat needs to be preserved longer, it is placed in the freezer.

- Poultry meat is stored in the freezer at a temperature not exceeding -10°C and a humidity of 85 - 90%. In industrial refrigerators, the shelf life is 15 days.

Storing poultry chilled

You can store poultry meat in the refrigerator if:

- A temperature that does not exceed +2°C.

- Air humidity, which should be at the level of 80 - 85%.

Storage of meat in such conditions is possible for no more than five days. A longer shelf life is provided in the frozen state.

Freezer storage

Poultry meat is stored in the freezer in polyethylene bags or thick paper. This will prevent the meat from actively losing moisture and freezing to the freezer.

The shelf life of poultry meat in the freezer depends primarily on temperature indicators.

At -12°C, according to the rules, a packaged whole carcass will be preserved for 8 months, without significantly losing its nutritional value.

Lower storage temperatures increase the shelf life of poultry. So, at -15°C it can last up to 10 months. And a temperature of -18°C ensures its reliable storage for up to 12 months.

Thawing of meat should occur gradually, at room temperature. If you place it in the microwave or under hot water, it will lose some of its nutrients.

How to store raw chicken

Chilled

If you are sure that the bird was slaughtered yesterday, then the shelf life of the chicken chilled in the refrigerator is up to 5 days from the date of slaughter. If the slaughter date is unknown, do not take risks, start cooking - by tomorrow the chicken may be covered with mucus.

Steamed (freshly slaughtered) chicken should not be placed in the refrigerator or cooked immediately - the meat must ripen. Biochemical processes in chicken after slaughter take place within 2–3 hours. This is how long a chicken should be at room temperature after slaughter. Otherwise it will be tasteless. Next comes cooling.

There is only one place to store raw chicken - the refrigerator. If you need to store parts of a carcass or fillet (breast), then the storage conditions and rules are the same.

Note to the hostess

You can put the chicken in the refrigerator wrapped in paper or a plastic bag. There should be a hole in the bag so that the chicken can “breathe”.

Frozen

If there is chicken, but there is no need for meat, it is sent to the freezer. Can already chilled chicken be frozen? The answer is simple - yes. To do this, just wrap the carcass in paper or a plastic bag and place it in the freezer.

Chicken can be stored in a household freezer for 5–7 months, provided it is not defrosted.

Thawed

Once the chicken has been thawed, it cannot be re-frozen. If the question arises about how long defrosted chicken can be stored in the refrigerator, then you can keep it there for no more than 12 hours. In defrosted chicken meat, the muscle fibers have already lost their structure, and the spoilage process will proceed much faster.

However, if there is no need for meat, the chicken can be prepared using the chosen method and the finished dish can be frozen.

Note to the hostess

Finished chicken, frozen in portions, can be stored in the freezer for 3 months. Please note that this product is edible, but you will not get pleasure from eating it.

By-products

Chilled liver, heart, gizzards should be cooked or frozen as quickly as possible. By-products should not be stored in the refrigerator for longer than 18 hours.

Deterioration processes occur rapidly in such tissues. The reason for this is intensive contamination with microorganisms. Do not buy offal for future use.

Offal can be kept in the freezer for 2 months at -8 °C and 6 months at -18 °C

Freezing carcasses

If hunting is done in winter, game can be frozen not only at home, but also in the natural environment: in the cold, hanging or in the snow. But it should be borne in mind that with this method of storage, game carcasses quickly become unusable when defrosted and lose their taste. For long-term storage, it is advisable to freeze meat at home by placing the meat in the freezer at a temperature of –18–23 °C; meat is not frozen at temperatures below –25 °C; there is an opinion that this way it loses its beneficial properties.

As preparation for long-term storage, game carcasses must be freed from dirt accumulations and entrails. Game meat frozen to a solid state can be stored for a long time - for 6 - 9 months.

How to store cooked chicken

After cooking the chicken, it is better to store it in the same container in which it was cooked. Once cooled, simply place the dish in the refrigerator.

If there is a need to take away some of the chicken meat and broth, then after that the remains must certainly be boiled. Then cool again and place in the refrigerator again.

Boiled

When boiling broiler, it is better not to eat broth. The chicken should be removed, placed in a container with a lid, and cooled. Next put it in the refrigerator.

Do you know that…

The broiler grows very quickly. Intense metabolism contributes to the accumulation of cellular metabolic products in meat. When boiled, they go into the broth - these are not useful substances for the human body.

Homemade chicken broth is delicious and flavorful. It perfectly helps soften coughs and soothe sore throats. Store boiled chicken in broth in the refrigerator for up to 2 days. Without broth - the same amount.

The broth can be frozen in portions and used as needed. Repeated freezing is unacceptable.

When asked how long frozen boiled chicken can be stored, you can answer - up to 3 months, provided that the freezer does not defrost.

Fried

Fried chicken is good hot. If there are leftovers after a meal, they are placed in a container and placed in the refrigerator. Fried chicken can be stored in the refrigerator for no more than 12 hours.

You can also freeze the product, but after defrosting it will be tough.

Smoked

The smoked product should be treated with caution. The slightest violation of technology can lead to insufficient heating of the carcass inside. It is better to give preference to small parts (wings).

When purchasing, take a close look at the product. If a white coating is noticeable on the folds of the skin, refuse to purchase. This indicates the beginning of the growth of microscopic fungi.

The product can be stored in the refrigerator for no more than 24 hours.

Grill

Grilled chicken is delicious hot. If it has cooled down and there is a need to preserve the product, then it is wrapped in paper or placed in a container and stored in the refrigerator for no more than 12 hours.

Pickled

A properly prepared classic (water, salt, sugar, vinegar, spices) marinade is already a preservative. You can store chicken in it without refrigeration for up to 2 days, in the refrigerator for up to 5. At the same time, the product will be tasty and will not spoil.

If something else is used as a marinade (sauces, kefir, etc.), then store the preparation only in the refrigerator and for no more than 12 hours.

Note to the hostess

If the chicken is marinated and removed from the marinade, it can be stored in the refrigerator for no more than a day.

How to process and store game bird carcasses

The hunted bird should not be placed immediately in a backpack or bag. It must be straightened and hung by the head or placed on a branch and allowed to cool in this position. During walking hunts, small swamp and meadow game can be hung by the heads from the handles of the game bag, and medium and large game can be carried suspended behind the back.

In birds, self-digestion of food continues for some time after slaughter, so at the first opportunity, the harvested game is cleaned of dirt and any debris, the blood is wiped off with moss or a dry rag, and the intestines are removed. Then, when stored fresh, the abdominal and oral cavities are filled with sprigs of juniper, spruce, wormwood, nettle or onion slices. You can sprinkle your mouth and abdominal cavity with salt before doing this. Finally, having straightened the feathers, the carcasses are hung by the heads in a cool place protected from flies. A good place is juniper bushes, where no insects are found. To protect against flies, you can use a gauze canopy, or you can “fumigate” the carcasses with thick fire smoke.

Game intended for storage should not be washed with water or processed in the rain. Game, killed on the spot from an average distance and the corresponding shot number, has a pleasant appearance, is better protected from the penetration of bacteria and does not spoil longer. Depending on the outside temperature, game treated as described above can be stored for a period of from two days to two weeks. It is recommended to transport game in nets or baskets.

There is another way to preserve game fresh, which can be used in the spring. Since ancient times, the population of the tundra has been able to preserve hundreds of hunted moulting geese and ducks for a very long time in the following way: in a dry place, they cut a turf of moss to the layer of permafrost, remove it and, on the resulting area, place the killed birds on their tails tightly to each other, after which The sides and top are covered with a double layer of turf. The cold from below and moss, which has disinfectant properties, reliably protect game from spoilage throughout the year.

Only fresh poultry that has no signs of spoilage and is not crushed with shot can be stored for a long time. More or less long shelf life of game is ensured by preservation methods such as freezing, salting and smoking. You can freeze poultry until it becomes solid in home refrigerators at a temperature of minus 10 - 15 ° C, followed by storage for one month. Before freezing, remove dirt, blood, intestines, smooth the feather cover, tuck the head under the wing, and either extend the legs along the tail or press them against the carcass.

Under natural conditions, long-term storage of upland game for late autumn and winter slaughter is possible in areas with stable winters. The poultry is frozen until solid at a temperature not lower than minus 10 ° C and stored for up to 6 - 9 months. either in a suspended state or on shelves at a temperature not lower than minus 8° C. Storage temperatures below 25° C are not advisable, as this reduces the quality of the meat. Game intended for curing must be plucked as soon as possible after slaughter. Then the carcass is singed, preventing the skin from burning, cleaned of any remaining fluff and feather stumps, and gutted.

To do this, the chest and abdomen are cut longitudinally to the anus; the area around the hole is cut out. The head and legs are separated and used along with the stomach, heart and liver. The carcass is thoroughly washed in cold, clean water and squeezed out of the water. When dry salting in early spring and late autumn, salt is taken at the rate of 70 g per 1 kg of game; in late spring and summer-autumn, the amount of salt is increased to 120 g per 1 kg of game weight. To salt per 1 kg of meat add 3 g of crushed juniper berries, thyme or garlic, 2 g of sugar and, if desired, 1 g of potassium or sodium nitrate to preserve the color of the meat. Everything is mixed and a curing mixture is obtained. Rub the carcasses outside and inside. The dry season ends by placing dense rows of carcasses in a barrel (with a half-centimeter layer of salt at the bottom), sprinkling each row with salt and adding black peppercorns and bay leaves (10 g per 1 kg of game). After aging for a day, oppression is placed in the barrel (2 - 3 kg per 10 kg of game). On the fifth day, complete sedimentation occurs and the barrel can be sealed.

With the mixed salting method, on the fourth day after dry salting in the manner described above and capping the barrel, cooled brine is poured through the hole in the lid until the container is completely filled. Brine is prepared at the rate of 1.8 - 2.5 kg of salt per 10 liters of water, the solution is boiled until the salt is completely dissolved, then cooled. There is a method of salting game by extrusion. It can be used for an accelerated salting method before smoking. The game must be fresh, without significant damage to the skin, so that the brine does not leak out. Brine with a strength of 25% (3.0 kg of salt per 10 of water) must be filtered. For 1 kg of game meat, 60 - 80 ml of brine is consumed, which is injected into various parts of the carcass: 2/3 injections are made into the front part of the carcass and 1/3 into the back. About 10 ml of brine should be consumed per injection. The needle is immersed to such a depth that the brine penetrates into the joints and under the bones.

Carcasses salted in this way are placed in a barrel using the above method and after 3 days of aging, they are filled with brine. Carcasses intended for smoking are kept for 1 day after extrusion.

You can smoke game hot or cold in a smoking pit dug on the slope of a river or ravine. First, they dig a ditch up to 2 - 3 m long with a width and depth of 25 - 30 cm. The walls of the ditch must be lined with brick or coated with clay, then covered with old iron or slate and sprinkled with earth. At the end of the groove, install a box measuring 1 x 1 x 1 m or a barrel without a bottom. To regulate the draft, the firebox must be covered with a piece of iron. The best firewood is bird cherry, alder, ash, aspen, apple tree, as well as reeds, damp straw, and dung. To add flavor, juniper, wormwood, and thyme are added to the fire.

The most suitable game for smoking is dry-salted and extruded. Before smoking, the carcasses are washed with water and dried under a canopy for 5 - 10 hours. Then the carcasses, wrapped in gauze, are hung on hooks to the crossbar and the box is covered with burlap (for cold smoking) or a wooden lattice (for hot smoking).

When hot smoking, in the first hour the temperature should be about 80 ° C. The process of hot smoking large game lasts 4 - 4.5 hours, medium game - 3 - 3.5 hours. After every hour, the carcasses should be turned. Hot smoking uses drier material and maintains a medium-density smoke. Cold smoking uses a more moist combustible material. To make firewood smolder and produce more smoke, cover it with sawdust from deciduous trees. The entire smoking process lasts up to 12 hours at a temperature of about 30° C without turning the carcasses. First, the carcasses are smoked in medium-intensity smoke, then low. After the end of smoking, the carcasses are freed from gauze, wiped with a firebox dipped in vegetable oil, and weighed in a dry room with a temperature of 12 - 15 ° C for cooling and aging: after hot smoking - for 4 - 5 days, after cold smoking - for 10 days . Hot smoked game can be used for 40 days, cold smoked game - 3 months.

Cutting up game birds

It is easier to pluck game that has been stored in a pen for several days by pouring boiling water over the carcass. Do the same if it was stored frozen. After the carcass has been plucked, it must be singed - this removes the remaining fluff and kills microbes. Before scorching, the carcass is rubbed with flour, then the remaining feathers and fluff dry out and stand on end. Instead of singeing, remaining feathers and down can be cleaned off with a piece of lard wrapped in canvas. It is better to remove the skin from diving ducks and coots along with feathers and subcutaneous fat, as it contains an unpleasant swamp smell of blubber. During gutting, the head and paws are cut off, and the carcass is gutted, trying not to crush the gall bladder, and the lungs, which are bitter, are removed. The heart, liver, and cleansed stomach are eaten from fresh game. Wash the bird in warm water, without leaving blood clots. Prepared large birds can be cooked whole or divided into portions. Medium-sized game is prepared either whole or cut into halves. Small game birds (snipe, great snipe, woodcock, quail, corncrake, etc.) are prepared as a whole carcass.